During this time, I came across a similar but less output power rated product from a big brand manufacturer, Havells. I also went to a whole dealer’s area in Hyderabad where all electrical contractors and builders came to buy electrical material at wholesale prices. There I saw a few low-cost products which were manufacturer in China. This was a little concerning. I researched for some additional features that I could embedded into the product to make it unique against competition. I came up with a thought to add a new chip which had the capability to sense load current requirements and adjust the output accordingly and when no charge current is needed it would automatically turn off. It also provided additional overheating and over current protection. However, this new chip would be the most expensive component on the bill of materials. We brainstormed on this and decided to make three variants of the product

1. Standard 5V, 5Watts 2.Standards 5V, 5Watts with On indicator LED and 3. Advanced 5V, 5Watts output with load current detection and auto power off feature.

We now had all the components to assemble and test a full product. However small or big a product that you design from scratch is, the experience of having a finished product in your hand is a special feeling. When we had the first fully assembled product, we signed on it as a symbol of our joy of creating something new.

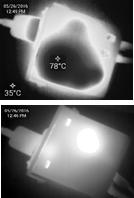

We tested the fully assembled product with varying load profiles programmed in the DC electronic load. We then used our phones to see how the product was performing. ||problem #8|| We took some measurements

and plotted the efficiency. For the advanced model, the efficiency was not at the levels we wanted but we accepted that and moved forward. We repeated the thermal tests with the enclosure.

In fact, we also did a bench marking against some of the competitor products and we were almost at part with them. || Problem 8 ||

To emulate extreme conditions, purely with the intent to ensure device safety, we used a hair drying to blow heated air towards the device and monitored the thermal shutdown features of controller as well as the load sensing chip.

By now I had established some more contacts with the transformer manufacturers. One of them had become a good friend who volunteered to help with the hi-pot testing and leakage current testing. I had done this to make sure the design was compliant with the safety standards (UL60950) even before || Problem 9 || I could get the formal certification. These devices fell under a category of devices which allowed self-conformance declaration. There were consultants who helped us with the self-conformity declaration.