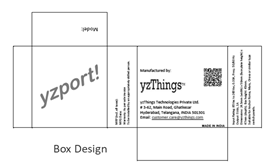

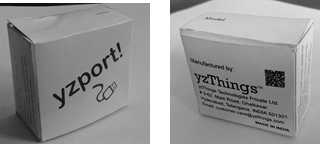

I didn’t want to call it a plain USB charging socket, so we named it yzport. The plan was to brand it as a futuristic advanced charger. To understand how the process of designing and making the packaging works, I reached out to a Pizza delivery box manufacturer. He showed how they do the packaging. || Problem 11 || But the problem was they got their designs done by a professional

designer. This was a problem like the MCAD model designing. I searched and found a designer in a street that was famous for printing presses and poster making. I somehow persuaded him to help me with the design. First, we did the print pattern based on which the cutout marking was prepared. We then made some paper mock-ups to see if the printed pattern was neat and if the dimensions were suitable for the device. After verifying, we finalized the packaging box design.

The printing person had a strict minimum order quantity but since that did not cost a lot I went ahead and got the lot produced at the minimum quantity he wanted.