Though there was a need for higher wattage chargers (> 10Watts), I made a conscious decision to start with a 5-wattage charger 1. To allow me to first build a full product development capability, not just from the design side but also the manufacturing, marketing and field deployment side. 2. It would help me kick start the sales cycle, establishing some level of cash flow.

Of course, we were exploring higher wattage design options whenever we had the opportunity.

So, for the first product i.e. the 5W wall panel mount USB charger I explored multiple topologies of which the flyback topology seemed more implementable quickly due to a. Availability of reference designs from controller manufacturers

b. Availability of manufacturers who could customize and supply the transformer

These two were the most critical components in the design.

After ordering and experimenting with a few controllers, I decided to go with the one from Power Integrations. This was because Power Integrations had a line up of controllers that would help me with higher wattage designs also, plus the salesperson with whom I was interacting was very supportive. He offered to provide quick samples and design support. This meant a lot to shorten the time to bringing my product to market and trigger the cash flow.

As promised the Power Integrations salesperson sent me a few samples of the controller within a few days, and also share some reference designs.

I wanted to see how the reference decide would work so asked one of my engineers to try and wire the circuit on a bread board, while I was trying to figure out how to arrange a suitable transformer.

From some of my social media groups Learnt about few transformer manufacturers in Hyderabad. I went to their factories and explained my requirement. Some were too busy to entertain my request but there was one manufacturer who showed empathy because I was trying to build a startup. He shared a sample specifications sheet that they would use as reference to customize a transformer and asked me to prepare something similar for my design. The sheet basically contained information such as required inductance, turns ratio, bobbin size, pin mapping, etc.

Honestly, I had underestimated the transformer design part and assumed I would get something off-the-shelf since the design was fairly standard. But that was not the case, it had to be fine-tuned to our design.

To fill the specification sheet, I had to design the transformer. It took me around three to four days full time to complete the design. I remember I had locked myself in a room sitting on the floor with different design references to first come up with the design approach and then the design specifications. Finally, I filled the sheet and sent it to the manufacturer.

Unfortunately, the transformer core type I design to was not available with the manufacturer || Problem 4 ||.

He was okay to source the core type but wanted a minimum order commitment from for it to make business sense for him. If I remember correctly, it was around 1 lac units, I was not in a position to commit to that kind of quantities during that time. So, I had to now look for other manufacturers.

A mentor had suggested to explore sourcing the transformers from other countries like China, he said it would be even cost effective. But I somehow was inclined to get it done locally so I reached out to the Power Integrations salesperson to see if he had any suggestions, and he did. He gave me contacts of a few transformer manufacturers around Delhi area, who he said might be able to help. I reached out to them and luckily one of them had the core type that we wanted. Even more, they had a fully designed transformer which was close to our requirement and some minor differences in the pin mapping. I ordered a few for testing.

By now the team had wired the circuit on a bread board. With all the loose wires, Controller IC mounted on a breakout board and connectors put together the design somehow worked. Of course, not to the specifications yet but it showed signs of life. We had to now tune it to make it work to our product requirements.

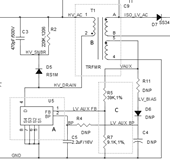

With this wired-up prototype we took some measurements and relooked at our transformer calculations and feedback loop component values. In principle, the controller operates in a closed loop manner, adjusting the pulse’s widths that it gives to the transformer proportionate to the feedback it receives from the other side of the transformer. This loop is critical to the design and defines the precision with which the overall output

levels are regulated to work within the design specifications.

Because this was a very crude form of wiring the circuit we did not expect it to work perfectly, we only wanted to verify the transformer’s design and get a feel of how the controller was actually working.

This gave us some valuable insights which we used and created a simulation model of the design. We then used the simulation model to play around with the design parameters.

Once we had confidence our design was reasonably good, we decided to make our own pcb.